I flipped the frame over, raised it up on jack stands and leveled it to prep it for grinding and tack welding the leaf spring mounts in place. I used the gantry crane and chain hoist. Having the frame upside down will make the work and welding a lot easier and make good welds and weld perpetration easier to check.

Author: oldschoolgasser

Rear End Preperations

Before I mount the rear end and suspension and tack weld the leaf spring mounts in place I disassembled the rear by pulling out the axles (with help from a slide hammer, and pulled out the pumpkin, drained some very black lube and ground down the old welds that were part of the old spring mounts in the 1960 oldsmobile from which it came.

Now that the rear housing is stripped down I will have it sandblasted, primed and I will paint the housing flat black and mask off the areas where the new leaf spring pad, ladder bars and new disk brake caliber mounts will be welded on and apply weld through primer and tack the mounts in place

Final Rear End Mock Up

After a couple of options to mount the rear end and suspension I decided to go back to the original factory mounting and to revert to a shackle instead of the slider to keep it more in line with the original function and appearance. Using the frame rails as the mounting points for the front and rear leaf spring mounts keeps the spacing and angles the same as they would have been with original rear end.

I ordered the parts from Speedway and as soon as the wheels that I ordered on October 17th show up I will mark the final location of the leaf spring mounts and and spring locations on the axle and remove everything to clean up the parts for welding. When I get everything back together after clean up I will need to put some weigh on the rear end to get the final mounting points right and the pinion angle dialed in and spot weld the mounts and axle while the weight is still on the chassis .

Rear End Mock up 2

I was missing some of the hardware needed to do a rear end mock up but Speedway came through and exchanged one of the sliders for me ( Thanks Derick ) and despite still missing the wheels I was able to get a better idea where of where the rear axle center line and leaf spring mounts fall on the frame. Not sure that I like the angle of the spring as it is now and I will need to think about how the angle of the spring will effect the action, ride and launch of the gasser. I might see what moving the mount will do to level the spring and how it might effect overall stance and how the axle will move thru its range of arc. I cut off the old spring perches from the axle that were below and too far out so I will grind off all of the old weld and clean up the top of the axle for the new mounts that I can tack weld on when I get everything where I want it and have the pinion angle close.

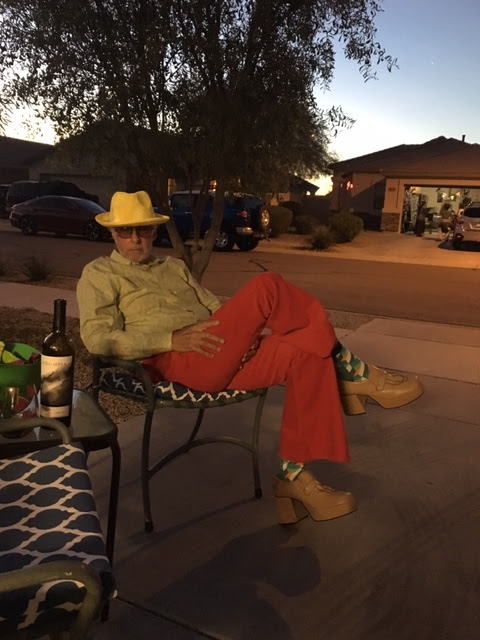

Real Old School

If you are going to build an old school gasser you need to visit the age of DISCO

Rear Suspension Mockup

While waiting for the tires and wheels to arrive I did a preliminary trail fitting of the rear end and suspension to see where the leaf spring mounts would land on the frame and how close to the needed width I would be. After the fit up I ordered the needed mounts and slide brackets from Speedway Motors along with a axle to spring mount kit. I will need to have the tires and wheels in order to get a better idea of where the total width is going to layout. I will also need to mount the body back on with the rear fenders off to get the definitive layout before I decide on narrowing the rear end and ordering fiberglass fenders if I need to cut them.

Body off Frame

On the Lift

I used two 3X4″ oak pieces under the rocker panels to spread the weight and used the lift to raise the body off of the frame

Tires & Wheels

I ordered the 8.20X15 white wall cheater slicks and Tri-Ribb wheels in a natural finish from Radir yesterday for the rear. Next week I will mock up the 9.3 rear end with springs, wheels and tires (if they arrive) and see where the spring mounts need to go and order them from Speedway. I am going to use slide mounts instead of shackles. With the rear temporarily in place I will be able to determine how much I need to narrow the rear and where the spring perches need to move to so that they hit the frame correctly.

Separating the body from the frame

Lifting the body up

I used a 3″ x 4″ piece of oak under each rocker panel to spread the weight and then used the lift to raise the body off of the frame

Roll out the frame

I rolled out the frame from under the body

Body on a dolly

I used more of the oak pieces to support the body and built a dolly with 4 Harbor Freight furniture movers. I built support points on the dolly where the body attached to the frame and lowered the body onto the dolly and rolled it out of the way

The 4 link suspension and rear end

I rolled the frame out the the outside work area so that I could remove the entire rear end and 4 link suspension. I put an ad on Craigslist but left the system tack welds in case the buyer wanted to see it fully installed.

The History of a 37 Ford Gasser Project

Background

I have always wanted to build another gasser, this time a nice one and not the POS Henry J that was unsafe at any speed and didn’t last even one run before the rear end exploded.

I and a few high school shop friends had built that car in a driveway with a gas welder, my mother’s vacuum cleaner with a spray paint accessory (made to spray pesticides). The driveline was from a Hudson and was a tight fit, we should have included the rear end but instead we welded the driveshaft to make it work. Tech inspection of the day allowed us to get in line one Sunday at the nearby track that was a converted WWII airstrip.

One run and done on the starting line was the result but a lot of fun and experience was gained along the way.

The Vision

While living in the Tampa FL area I was looking for a candidate in the early 2000’s, something old school that would not need a lot of body work, something that would have the look and function that a late 1960’s home built gasser would have had in the day.

The Car

I found a good candidate and was able to acquire the 1937 Ford 5 window coupe project donor from a private owner who was having it built at a shop as a street rod project. The project had stalled out when the dot.com boom busted and the cash need to complete the project had dried up.

The project included a very rust free and dent free body, a TCI chassis with a four link coil over rear suspension, ford 8.8 rear end, a Mustang II front end with tubular A arms and a 5.4 Cobra mod engine and AOD transmission along with a pile of other parts and pieces.

My plan for the car was always to build a period correct gasser as it would have been done in the late 60’s in the style it would have been built during the NHRA period of gassers, altereds and slingshot rail jobs.

Some concessions to time would be needed if I planned to ever actually race the car on today’s tracks but most of them would be for safety issues that would not distract from the appearance of the finished product.

The Parts

A 1960’s period correct gasser would require collecting period correct pieces including a complete new drive train, front and rear suspension, tires and wheels, interior pieces and attention to details such as ladder bars, fender-well headers, tilt front end, a mooneyes front mounted tank and ladder bars to complete the look and function of a mid 1960’s gasser

The Drive Train

The first task was to locate a period correct drive train that the rest of the needed pieces would be built around. Most of the high end gassers of the time were running blown hemi’s at the top end of the competitive scale but I envisioned a more typical home built gasser that would have been what a local competitor at a local track would have built.

My choice was a 425 ci Buick nailhead because it would be a little bit contrary to the small block Chevy that would have been the most readily available engine for a small budget engine of the day.

I was able to locate a running 425 cu in Nailhead in a 1966 Buick Electra 225 with a TH400 switch pitch transmission while working in St. Louis and I purchased the entire car and shipped it back to Vancouver WA.

I pulled the engine and trans together along with the driveshaft and transmission cross-member and other small pieces that I thought might be useful and scrapped the rest at a yard that was nearby and watched it ascend the conveyor belt to the crusher and grinder and come out the other end as small pieces of metal on their way to China, RIP faithful friend.

The engine will look great with long injection stacks, hilborn barrels and I will convert them to efi and hide the evidence to keep that old school look.

The Suspension

The front axle and suspension was next and again I sought out something unusual because the supply of Econoline and Dodge D100 vans was small and most had been picked over already. I was able to locate a complete 1967 Chevy van and negotiated a good deal on the complete front end suspension including steering gear and column. I had to remove it all myself in a muddy field in the rain but he did lend me a pickle fork and it was a complete system.

I removed the Mustang II front end as a unit but left it intact on the frame by cutting the entire front frame off in front of the firewall and leaving enough to make a strong connection to the new front frame when the time came. I sold the entire front end on ebay, put it on a pallet and shipped it freight to the buyer for his street rod project.

The rear end was another component that needed to be the right piece for the time and the 9.3 in Olds/Ponticas of the 1960’s we often used because of their availability and strength.

A 9” ford would be used today but this is the 1960’s and that unit was not yet the rear of choice in the great gasser wars of the day. I found a 1960 Oldsmobile with a complete rear end in Vancouver WA and added it to the pile-o-parts that I was building. I did not get the rear springs or shocks with the rear but I did find a 1965 Plymouth leaf spring pair in Phoenix AZ that had been prepared for a FX clone car but not used, the leaf pack had been disassembled, glass bead blasted and powder coated and it was only $50 and will only need hangers and shackles to work.

The hunt for a Econoline or Dodge D100 front seat goes on and I will be purchasing new Radir Tri Bar wheels and white wall slicks that I will need in order to plan the narrowing of the read end along with a new ring/pinion set, posi unit and axles to complete the rear along with home built ladder bars that I will make using ¾” rectangular stock and speedway front and rear mounts and axle attachment parts. I hope that the rear tires will fit in the rear fender but if not I will purchase a fiberglass pair and cut the radius out of them so that the pristine original steel rear fenders remain available for someone who might be restoring or street rodding a 37.

The Plan

In order to make sure I would be happy with the results of the completed project I built a complete 1/25 scale model with the correct styling cues, stance and paint scheme that I planned to use in the final assembly after all the rough-in construction is completed and it spends a little time in its rough state on the street to shake down the drive-train, suspension, steering and any redesign or tweaking that is needed before the tear down and final assembly with interior panels, paint, lettering etc.

As a former project manager and engineer I couldn’t resist making a complete project plan and budget tracking spreadsheet with enough detail and order to make tracking and accounting easier.

The Start

After moving the entire project from Tampa to Vancouver and then to Phoenix and the passage of almost 20 years I am finally ready to build the beast.

The first step needed was to separate the body from the frame so that I can remove (and sell on Craigslist) the existing rear end and 4 link suspension and begin construction of the rolling chassis including drive train and front end while test fitting the body along the way to avoid as much rework as I can along the way.

I used my shop two post lift to raise the body, roll out the frame with the rear end and built a body dolly to move the body out of the way of the lift while working on the chassis outside.