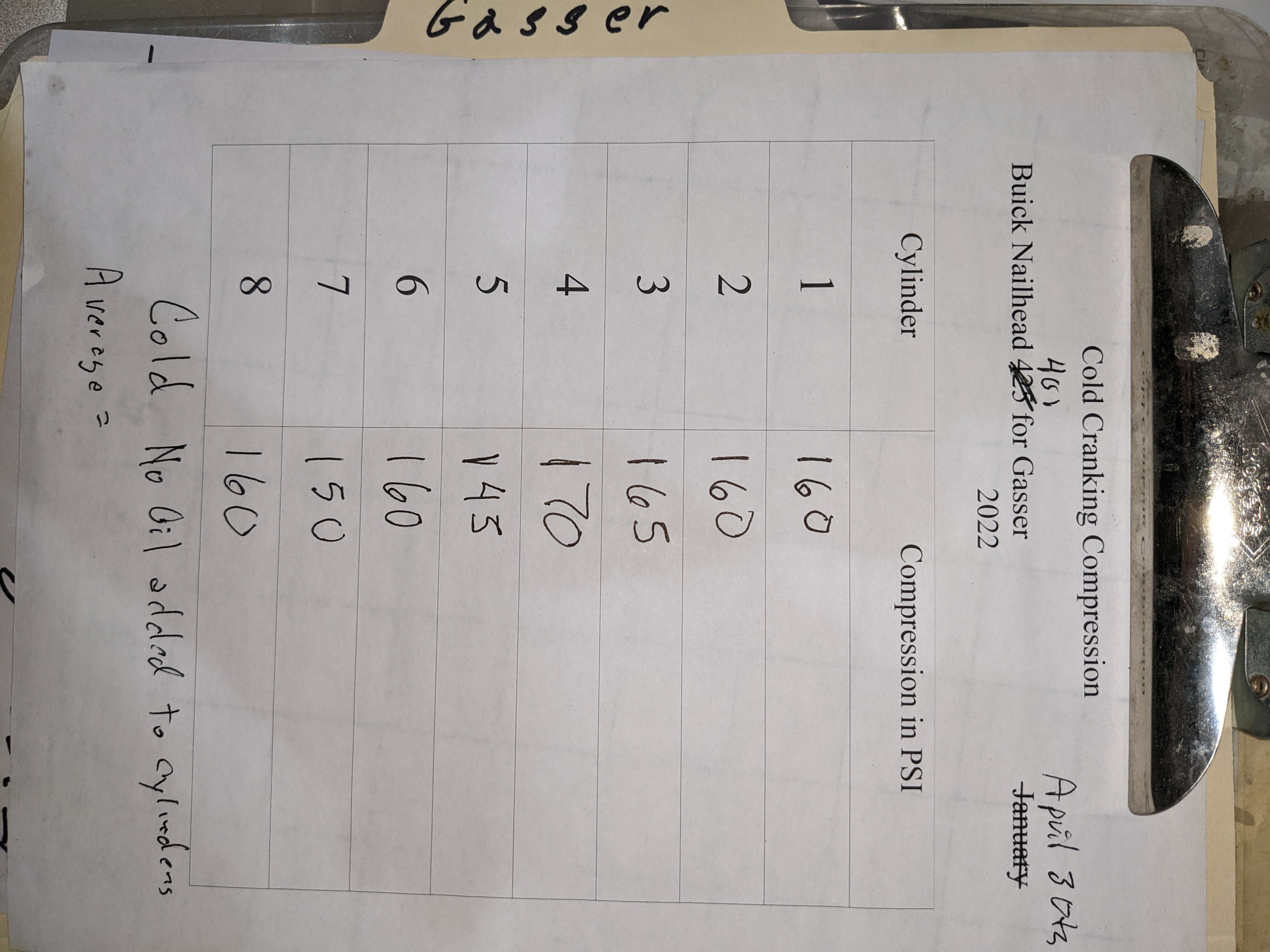

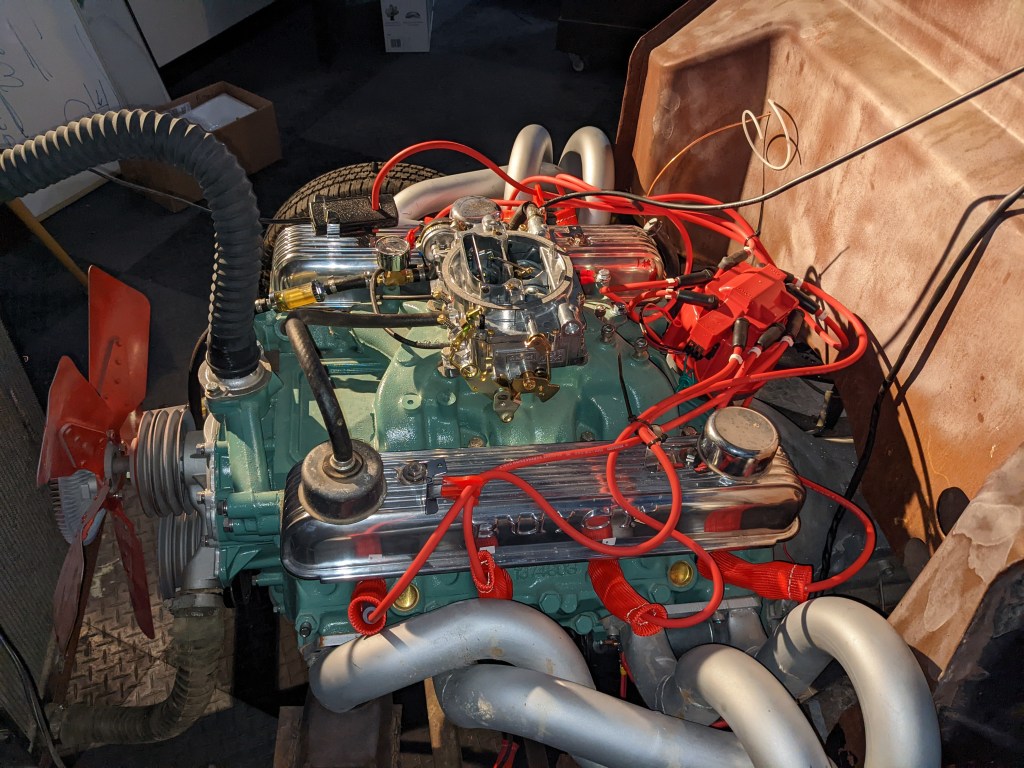

Once the 401 cubic inch Buick Nail Head was in the Gasser and all of the checks (like compression and #1 top dead center) etc were completed and the ignition system was installed and checked I checked that there was fuel pressure to the carburetor, oil level and oil pressure when cranking. I had installed switch for ignition power and a push button switch on the dash to turn the starter motor over.

I primed the carburetor and hooked up a timing light and the Gasser started right up and sounded loud and mean just like I hoped.

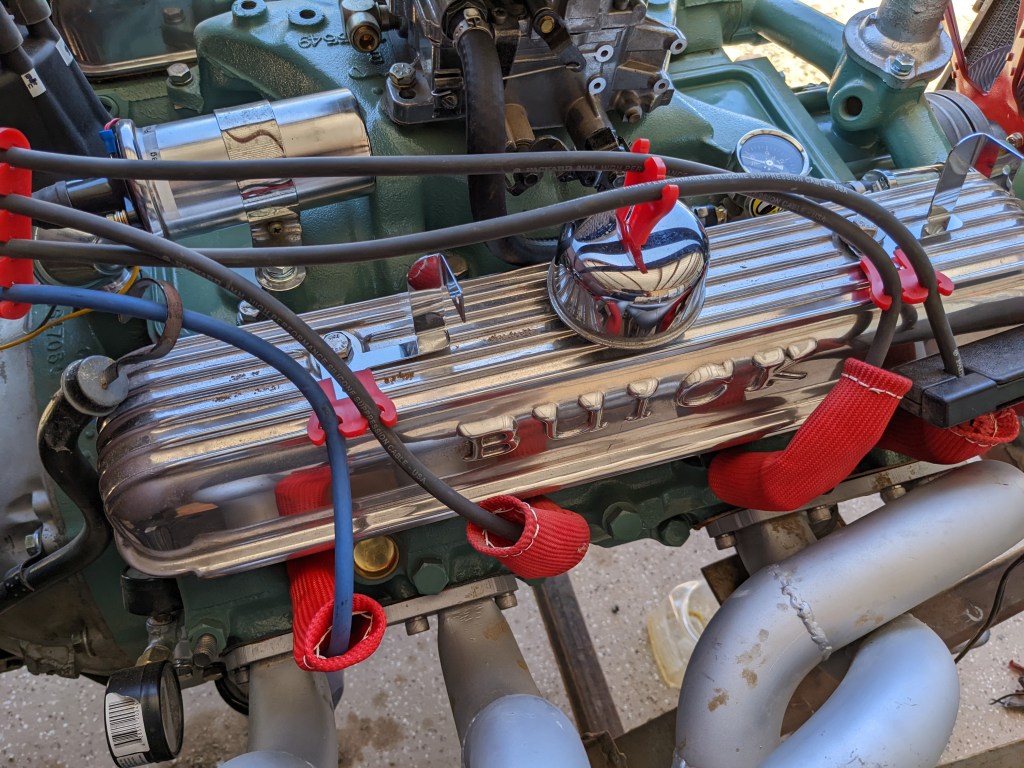

401 ci Buick NailHead Compression Check

The Gasser should be ready to start soon. The fuel pump, carburetor and distributor, ignition coil are on the motor and the spark plugs, spark plug wires, radiator and hoses and ready to install. I will find top dead center on #1 compression stroke and install the plug leads and set 20-30 degrees of initial advance and give it a few bumps with new premium fuel and a shot of starter fluid to see if it will turn over.

Precision Drive lines of Arizona

The Gasser needs a drive shaft

Old School Ladder Bars

I welded on the rear axle mounts for ladder bars on the rear end when I installed the 1960 Oldsmobile 9.3 rear end because I knew that a set of 8′ ladder bars painted red would give the Gasser that old school the side view look that I would want.

I will be obtaining the needed 3/4″ rectangular materials and do a little welding with the MIG when the summer heat leaves (109 today) and it gets into the 80’s early in the mornings

Gasser Starts and runs and is LOUD!!!

First start up Video

Starting the Gasser… July 5th 2022

video

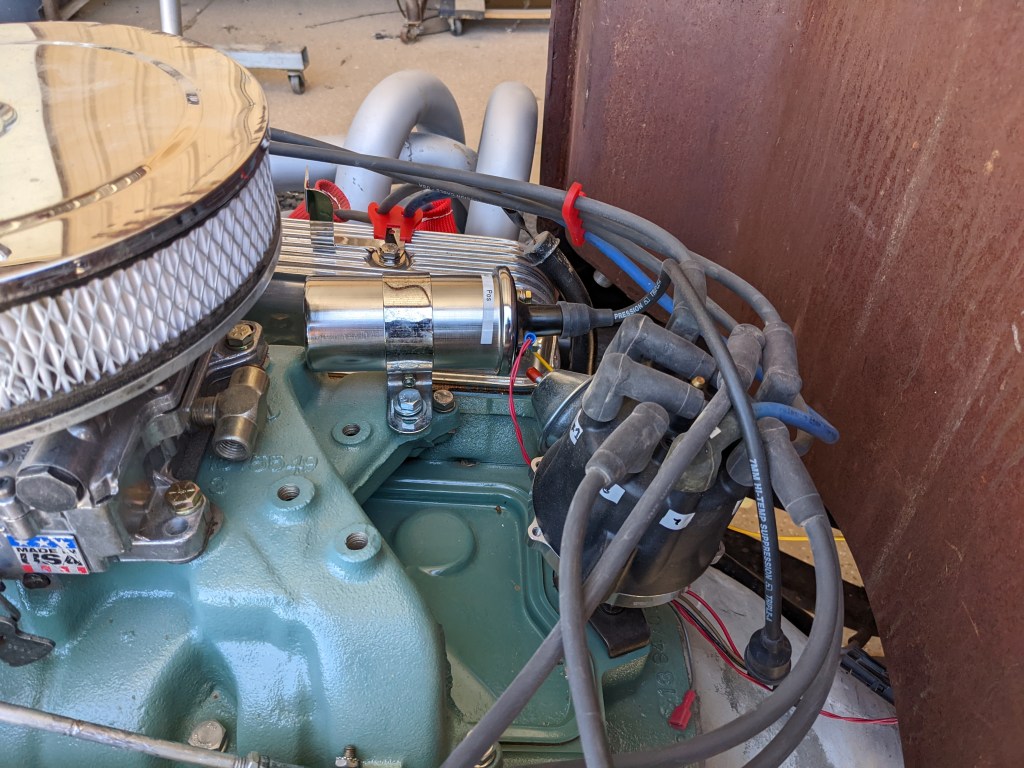

New Ignition System

I updated the engine with a complete new ignition system with a 50K volt coil built in. I turned the engine over by hand with my breaker bar with a compression gauge on the #1 cylinder until the top dead center marking on the dampener was a zero while the compression gauge showed #1 on the compression stroke. I then marked the position of the distributor rotor in the engine and labeled the distributor cap from 1 to 8 clockwise and using the firing order and the engine plug layout I installed plugs and ran plug wires 1 to 8 to the correct plug # 1 to 8.

With the new ignition system installed I used my timing light on each plug wire while turning over the motor to confirm that each plug and plug wire was operating.

Time to see if it will run

With the ignition sorted I turned on the fuel at the moon tank and cranked the engine over and checked that fuel pressure was at 6-8 lbs and flowing via the see through fuel filter.

With compression, fuel and ignition the engine should run or at least try.

She is alive!!!!!

Using the ignition power switch and starter button on the dash that had installed and tested and wired to the new distributor.

I checked the accelerator squirters in the carburetor, closed the choke and hit the starter and I was rewarded with a few bangs, a backfire or two and a loud exhaust note as the Gasser tried to come to life. I think she is ready to run pending a timing adjustment which is a two person job that me and few rowdy gear head guys can handle next.

New Carburetor

The carburetor I have been using is too big, is leaking and has no choke so I ordered an Edelbrock 1406 with an electric choke and is rated at 600 CFM

Adding the final details

With good compression and oil pressure I replaced the oil pump primer rod with the distributor and turned the engine over with the breaker bar to zero degrees on the harmonic balancer and checked cylinder #1 for top dead center, I checked that #1 was on the compression stroke by checking the valves on #1 to make sure both valves were closed. With the distributor in and the cap off I check the rotor and marked the cap 1 to 8 based on #1 at TDC on compression and ran the plug wires to the plugs following the firing order.

I wired + 12VDC from run terminal on the ignition to the coil and distributor for power and hooked up my timing light to another battery .

With compression, timing, ignition and fuel in the Carburetor (checked the accelerator pump squirters too. It should start if I wired the plugs correctly